Trunking vs Conduit vs Cable Tray: How to Choose for Homes, Shops & Factories

Cable Engineering & Selection Guide – By See Kwong Electric (Since 1958)

When people talk about electrical safety, they usually focus on cables and breakers. But one critical part is often overlooked:

👉 How the cable is contained.

Whether you’re wiring a house, shoplot, office, or factory, choosing between trunking, conduit, or cable tray has a big impact on:

Safety 🔒

Heat dissipation 🌡️

Maintenance 🔧

Cost 💰

Long-term reliability

At See Kwong Electric, with experience dating back to 1958, this guide explains cable containment in simple, practical Malaysian terms.

Why Cable Containment Matters (More Than You Think)

Cable containment is not just for neatness.

A proper system will:

Protect cables from physical damage

Control heat build-up

Reduce fire risk

Make inspection and maintenance easier

Comply with Suruhanjaya Tenaga (ST) & MS IEC standards

Wrong choice = overheating, premature cable failure, and messy upgrades later.

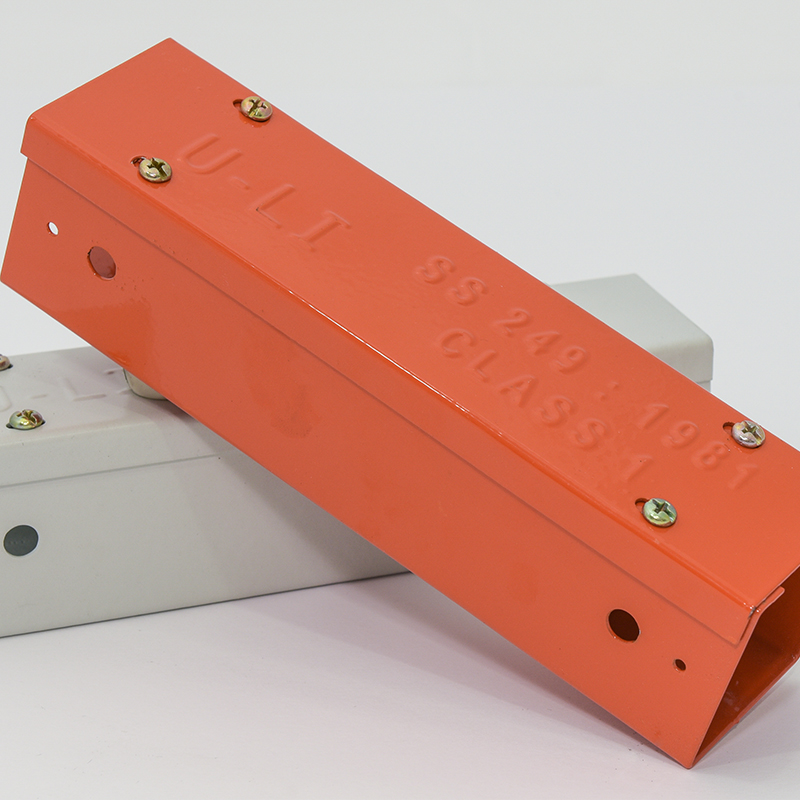

1. Cable Trunking – Common, Clean & Practical

What Is Trunking?

Cable trunking is a rectangular enclosed system, usually made of:

PVC (most common for homes & shops)

Metal (for commercial & industrial use)

Where Trunking Is Best Used

✅ Homes

✅ Shoplots

✅ Offices

✅ Light commercial areas

Typical applications:

Surface wiring

Renovation projects

Areas where hacking walls is not possible

Pros of Trunking

✔ Easy to install

✔ Clean and tidy appearance

✔ Easy to add or remove cables

✔ Cost-effective

✔ Ideal for retrofit works

Cons of Trunking

❌ Limited heat dissipation

❌ Not suitable for very high current cables

❌ Can look bulky if poorly planned

💡 Pro tip (Malaysia practice):

Always size trunking with at least 30–40% spare space for future cables.

2. Conduit – Maximum Protection & Hidden Finish

What Is Conduit?

Conduit is a round pipe system used to run cables:

PVC conduit (most common)

GI / metal conduit (industrial & fire-rated areas)

Cables are pulled through, not laid openly.

Where Conduit Is Best Used

✅ Concealed wiring in homes

✅ Concrete slabs & walls

✅ Factories with harsh conditions

✅ Fire-rated or mechanical protection areas

Pros of Conduit

✔ Excellent mechanical protection

✔ Clean, hidden installation

✔ Better fire resistance (metal conduit)

✔ Long lifespan

Cons of Conduit

❌ Harder to install

❌ Difficult to add cables later

❌ Labour cost is higher

❌ Poor planning = cable pulling nightmare

⚠️ Common mistake:

Overfilling conduit. This causes:

Cable damage

Overheating

Failed inspections

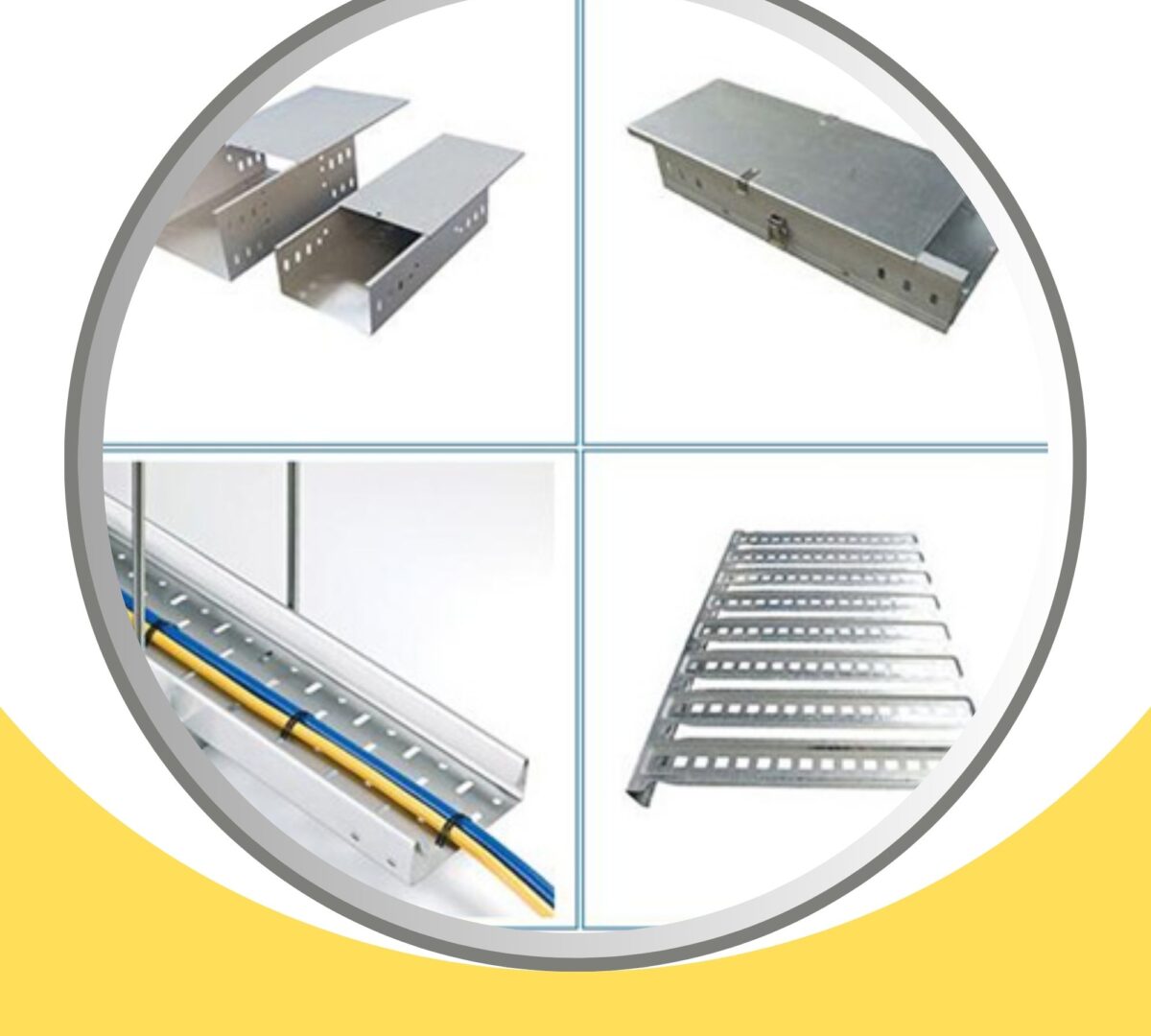

3. Cable Tray – Industrial Standard for Power & Data

What Is Cable Tray?

Cable tray is an open support system, usually made of metal, designed to carry:

Power cables

Control cables

Data & instrumentation cables

Common types:

Ladder tray

Perforated tray

Wire mesh tray

Where Cable Tray Is Best Used

✅ Factories

✅ Data centres

✅ Commercial buildings

✅ Plant rooms & risers

Pros of Cable Tray

✔ Excellent heat dissipation

✔ Easy inspection & maintenance

✔ Ideal for large cable quantities

✔ Easy future expansion

Cons of Cable Tray

❌ Not suitable for homes

❌ Needs proper earthing

❌ Requires good cable management

❌ Exposed – not for public areas

💡 Malaysia factory standard:

Cable tray is preferred for high-current LV cables to reduce heat build-up.

Quick Comparison Table (Malaysia Context)

Cable Engineering Considerations (Very Important)

When selecting containment, always consider:

1. Heat Dissipation

Trunking & conduit trap heat

Cable tray allows heat to escape

This affects current rating (derating factor).

2. Cable Size & Quantity

Large cables = tray or large trunking

Too many cables in small space = fire risk

3. Environment

Moist areas → PVC or coated metal

Factory → metal conduit or tray

Public areas → enclosed systems

4. Maintenance & Expansion

Future upgrade planned?

→ Trunking or tray is easierFixed design?

→ Conduit is acceptable

Common Mistakes We See in Malaysia

❌ Using trunking for heavy factory power cables

❌ Overcrowding conduit beyond safe fill ratio

❌ No spare space for future cables

❌ Poor support spacing on cable trays

❌ Mixing power & data without separation

These don’t fail immediately — they fail after months or years.

How See Kwong Helps with Cable Selection & Containment

At See Kwong Electric, we don’t just sell cables and accessories.

We help you:

Match cable size with containment

Avoid overheating issues

Choose cost-effective but safe systems

Comply with ST & MS IEC requirements

Plan for future expansion

This practical knowledge comes from real projects since 1958, not just manuals.

Final Thoughts: Choose Once, Choose Right

There is no “one-size-fits-all” solution.

Homes → Conduit & trunking

Shops & offices → Trunking or tray

Factories → Cable tray & metal conduit

The right choice improves:

Safety

Reliability

Ease of maintenance

Long-term cost savings

If you’re unsure which system fits your project, it’s always cheaper to ask before installation.

📍 Visit www.seekwong.com

📞 Talk to See Kwong Electric — your trusted partner in Cable Engineering & Selection, since 1958