How Distance Changes Cable Sizing (Without Overcomplicating It)

When choosing electrical cables, most people in Malaysia focus on current (ampere) and cable size (mm²). That’s important — but there’s one factor that’s often overlooked and causes real problems on site:

👉 Distance

At See Kwong, we frequently see cables that are “technically connected” but practically underperforming — dim lights, weak motors, nuisance trips, and overheated cables. In many cases, the root cause is simple: the cable run is too long for the selected size.

Let’s explain this clearly, without complicated formulas.

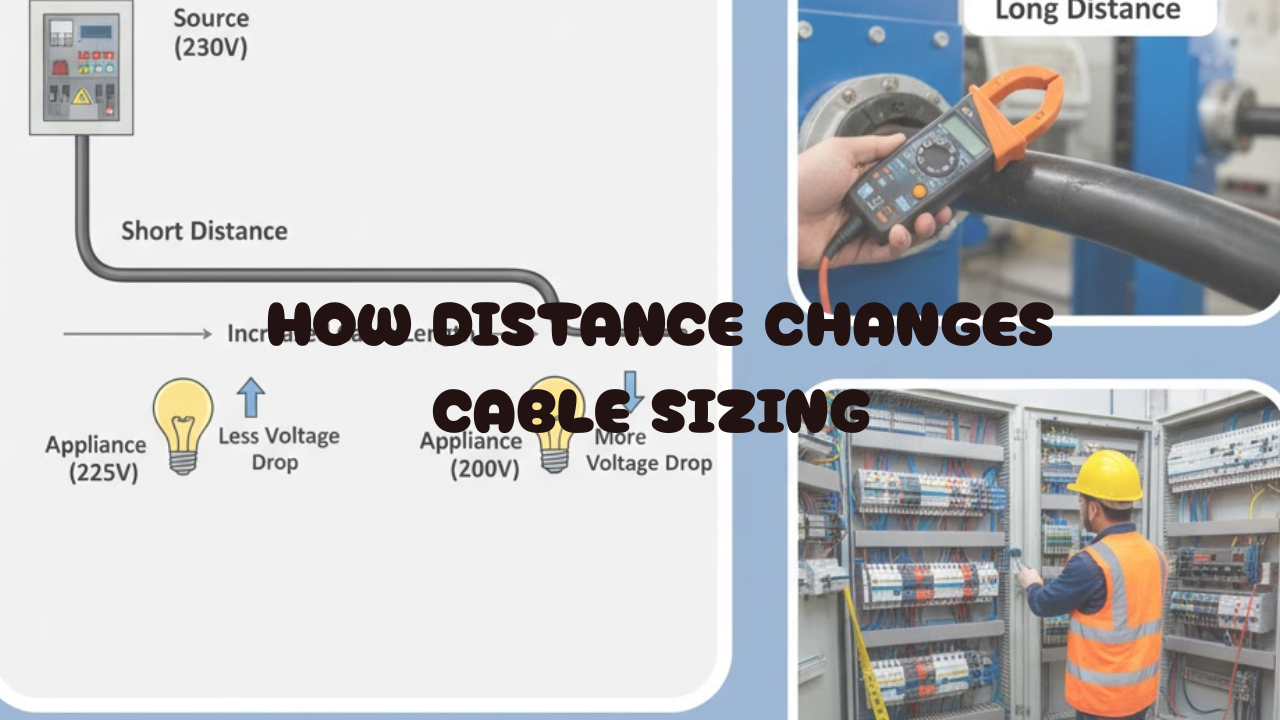

The Simple Truth: Longer Distance = Bigger Cable Needed

Electricity doesn’t travel perfectly.

The longer the cable, the more voltage drop occurs.

👉 Voltage drop means:

Less voltage reaches the equipment

Devices work harder to compensate

Heat builds up in the cable

Efficiency and lifespan are reduced

Short distance → standard cable size usually OK

Long distance → cable size must increase

What Is Voltage Drop (In Plain Language)?

Think of electricity like water flowing in a pipe.

Short pipe → strong water pressure

Long pipe → pressure drops before reaching the endElectrical cables work the same The longer the cable:

Why Voltage Drop Matters (Especially in Malaysia)

Excessive voltage drop can cause:

Lights not bright enough

Motors overheating or failing early

Air-conditioners not starting properly

Electronic equipment malfunctioning

Increased energy loss (higher bills)

In Malaysia, standard practice (based on IEC / MS standards) is to keep voltage drop within:

≤ 3% for lighting circuits

≤ 5% for power circuits

Anything beyond this is a design problem — not a product problem.

A Practical Example (No Math, No Stress)

Let’s say you’re wiring:

A 20A load

Using a 4mm² cable

Distance: 10 metres

✅ Usually OK

Now change only one thing:

Distance becomes 40–50 metres

❌ Suddenly:

Voltage drop increases

Cable heats up

Equipment performance drops

👉 Solution:

Increase cable size to 6mm² or 10mm², depending on the load and installation method.

Same current. Same equipment.

Only distance changed — AND cable size must change too.

❌ “Ampere Rating Is Enough”

Amp rating alone does not consider distance.

❌ “It Works, So It’s Fine”

It may work today — but long-term heating and voltage drop will damage equipment.

❌ “Bigger MCB Will Solve It”

Incorrect. Bigger protection without correct cable size is dangerous.

❌ “Contractor Always Use This Size”

Standard practice is not always correct for every installation.

Simple Rule of Thumb (For Early Planning)

While final sizing should always be calculated, here’s a general guide:

Up to 15–20m → standard size usually sufficient

20–40m → check voltage drop carefully

Above 40m → expect to increase cable size

Correct cable sizing:

Reduces heat

Prevents nuisance tripping

Improves equipment lifespan

Saves energy long-term

Improves overall system safety

How See Kwong Helps

✔ Supplying IEC / MS-compliant cable selection

✔ Suitable for residential, commercial & industrial use

✔ Support for long-distance and high-load applications

✔ Reliable cable brands with proven performance

Just tell us:

Load type & current

Distance of cable run

Installation environment